- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Mu-metal zero gauss chamber

- Home

- Mu-Metal - Magnetic shielding materials

- Mu-metal zero gauss chamber

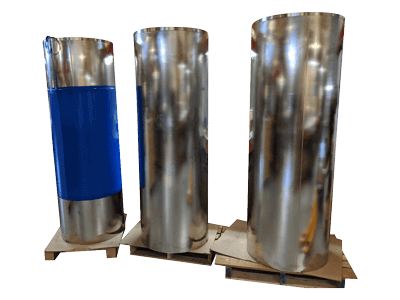

We offer 3-layer stock chambers designed with inner diameters of 76.0 mm, 152.0 mm, 229.0 mm, 305.0 mm, 457.0 mm, and 610.0 mm; and will custom fabricate any size or configuration required.

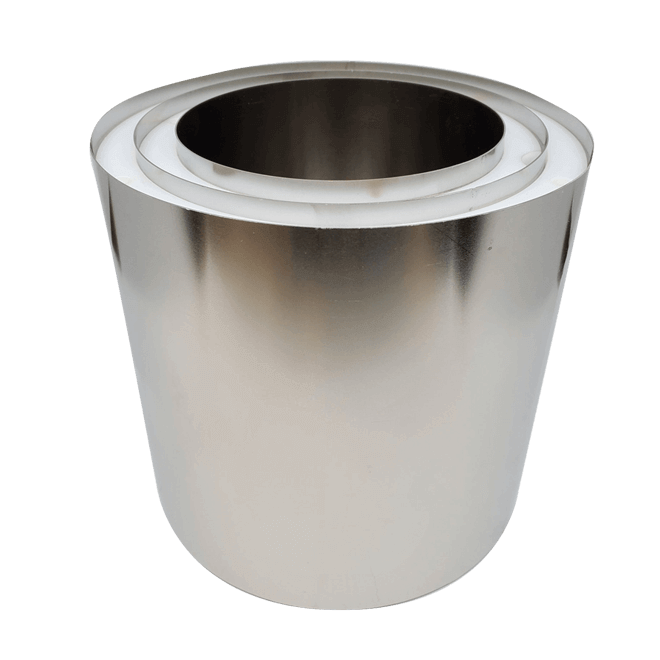

Our chambers are preferred because they are made from high permeability (µ) mu-metal, which provides a consistent, low field test area. Our standard 3-Layer Zero Gauss Chambers are designed to attenuate external static and low frequency A.C. fields 1,000 to 2,500 times. Residual fields of <5nT (.05mG) and low noise (<100fT/sqrtHz) can be achieved with proper degaussing methods.

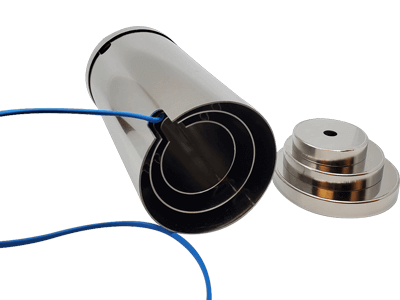

To achieve the lowest magnetic levels within the chamber and for providing optimum long term stability and uniformity of the internal magnetic field levels, the periodic use of a Degaussing Coil is recommended. We offer both standard and optional high temperature insulated Degaussing Coils.

The metal have been used worldwide by many universities, private research companies, national laboratories and OEM companies required to provide evidence of military or consumer regulatory compliance.

We have design and produced many custom configured chambers; up to 5-layers, with degaussing systems, up to 2.0 meter inner diameter and over 90 meter long. If you require a custom chamber, our technical team can provide CAD design, testing, data collection and verification services to support your project.

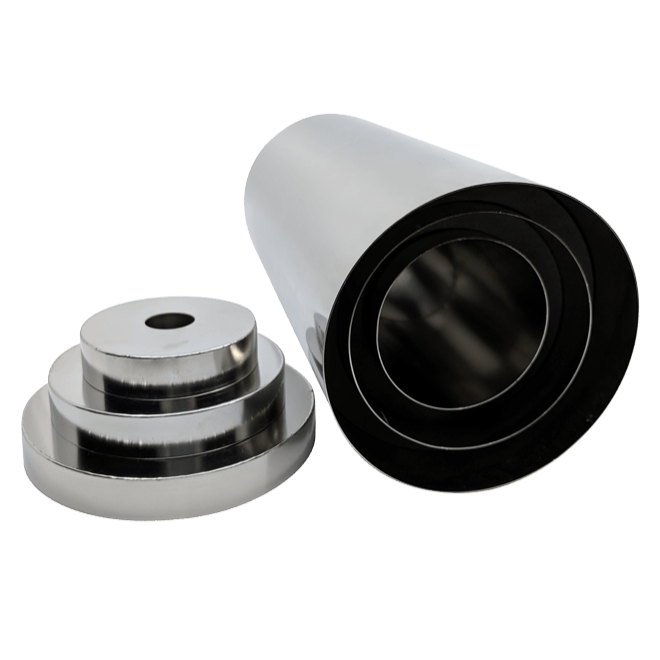

- Construction: Full heliarc butt seam welds. Covers slip-fit over cans

- Anneal: Perfection Annealed after fabrication to our specification

- Finish: None Required

- Assembly: non-magnetic layer spacers for isolation & alignment

- Degaussing Coil: Optional – used to reduce residual magnetism. Wrapped outside of inner layer

- Cradle: Included – a non-magnetic Cradle to hold the chamber in horizontal position and reduce vibrations.

Product specifications

| Item Number | Thickness per Layer | Inside Diameter | Inside Depth |

|---|---|---|---|

| ZGC-1 | 0.64 mm | 76.0 mm | 229.0 mm |

| ZGC-2 | 0.64 mm | 152.0 mm | 381.0 mm |

| ZGC-3 | 0.76 mm | 229.0 mm | 686.0 mm |

| ZGC-4 | 1.00 mm | 305.0 mm | 914.0 mm |

| ZGC-5 | 1.58 mm | 457.0 mm | 1372.0 mm |

| ZGC-6 | 1.58 mm | 610.0 mm | 1829.0 mm |

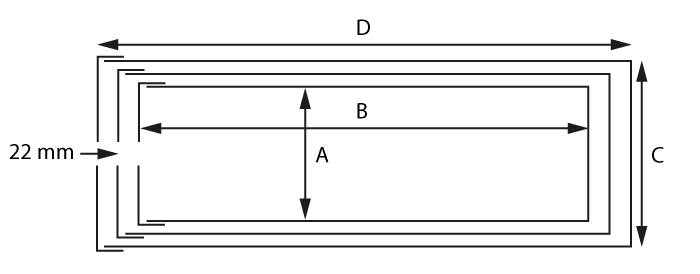

Dimensions

| Partnumber | A Min Inside Diameter |

B Min Inside Depth |

C Max Outside Diameter |

D Max Overall Length |

Number of Layers |

Thickness per Layer |

|---|---|---|---|---|---|---|

| ZGC-1 | 76 mm | 229 mm | 133 mm | 286 mm | 3 | 0.64 mm |

| ZGC-2 | 152 mm | 381 mm | 210 mm | 438 mm | 3 | 0.64 mm |

| ZGC-3 | 229 mm | 686 mm | 286 mm | 743 mm | 3 | 0.76 mm |

| ZGC-4 | 305 mm | 914 mm | 362 mm | 972 mm | 3 | 1.00 mm |

| ZGC-5 | 457 mm | 1372 mm | 569 mm | 1483 mm | 3 | 1.58 mm |

| ZGC-6 | 610 mm | 1829 mm | 721 mm | 1940 mm | 3 | 1.58 mm |